Rope Access Equipment Inspection Checklist

Essential rope access equipment checklist.

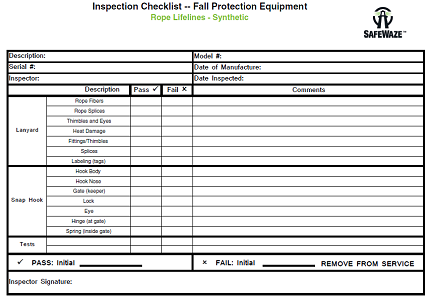

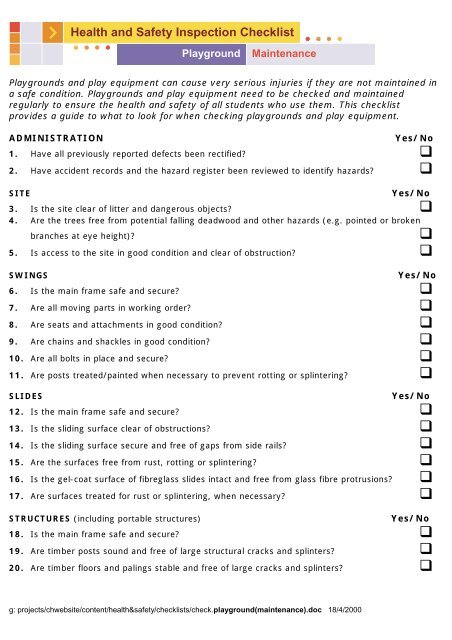

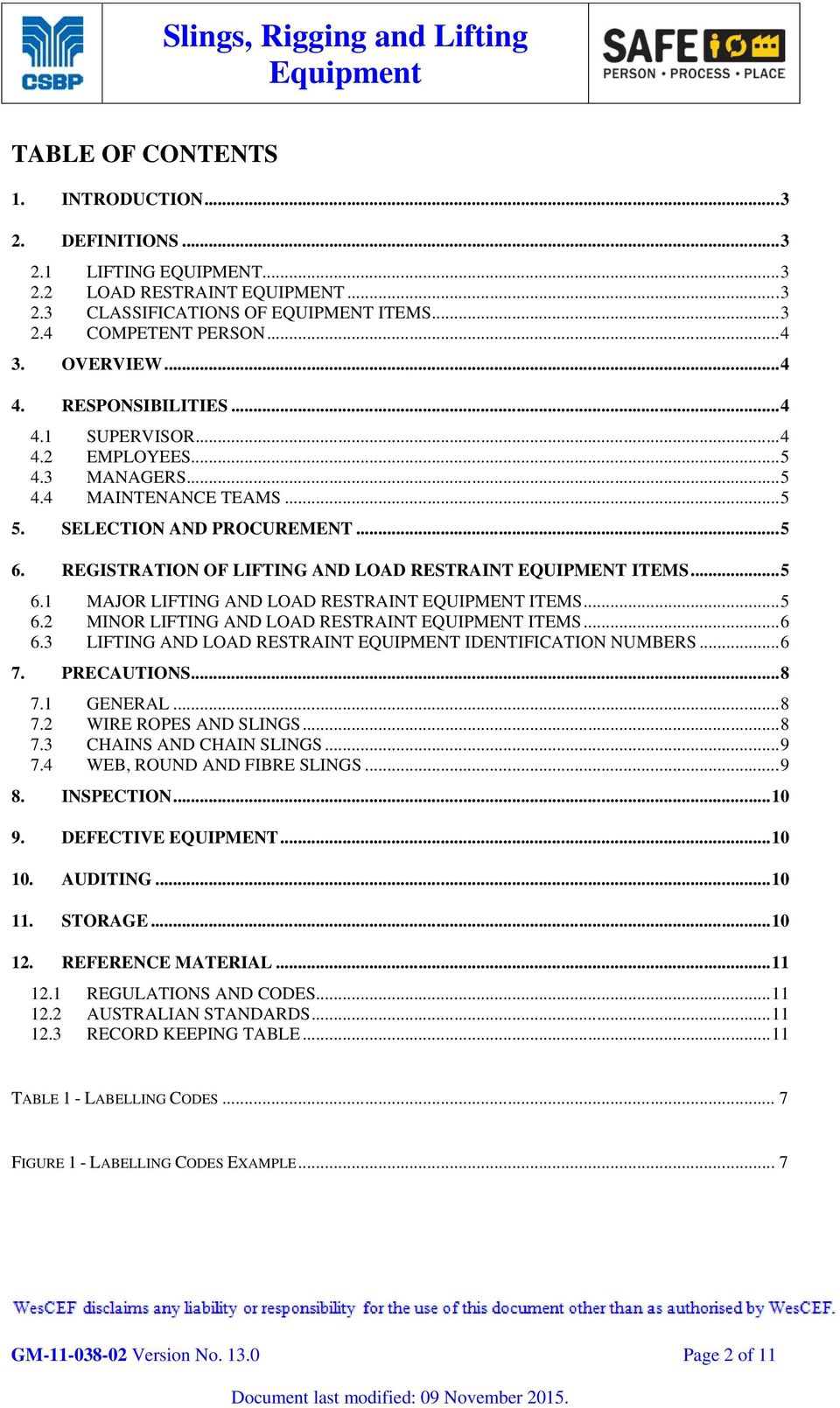

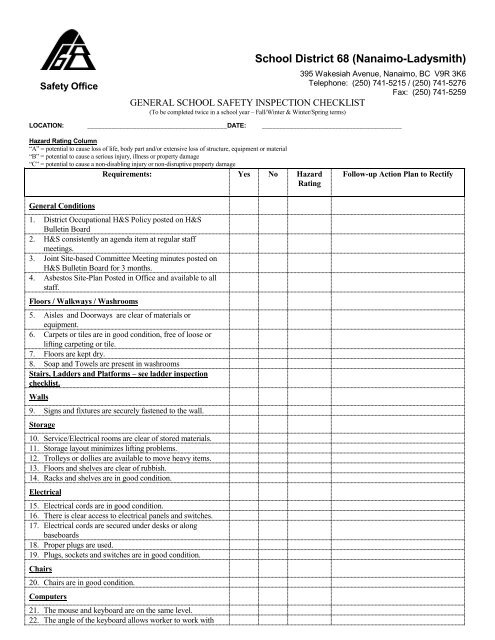

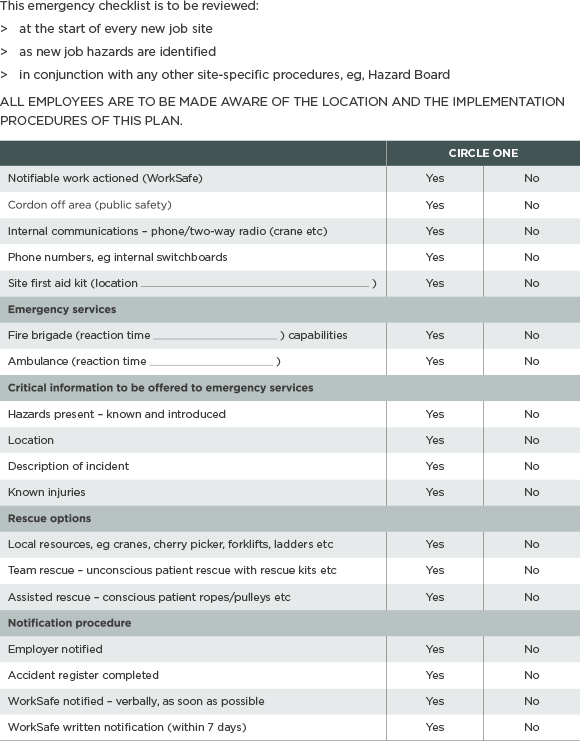

Rope access equipment inspection checklist. Below are suggestions and a general checklist to ensure that your rope grab assembly is working correctly. The qualified person should check the product user manual for information on how to replace damaged. On kernmantel ropes feel for unusually soft or hard areas on sheath and core. These are checklists run in conjunction with permit to work ptw or safe job analysis sja schemes to try and ensure that everything is in place from the start for the job to be done safely.

Rope suspends the technician and allows enough line to reach the work location. In certain situations rope access can provide a cost effective alternative to scaffolding and other more time consuming methods of work positioning. O the procedure addressing the inspection testing and maintenance of all fall protection equipment. After a fall occurs the rope grab assembly must be removed from service and checked by a qualified person per osha.

The following guidelines shall be followed. Two ropes are required. Washing ropes slings etc will also remove ingrained dirt which if left can cause internal wear and thus reduce the lifetime of a product. Please ensure any equipment being sent in for inspection is washed and dried before being sent as equipment cannot be easily or fully inspected when covered in grime.

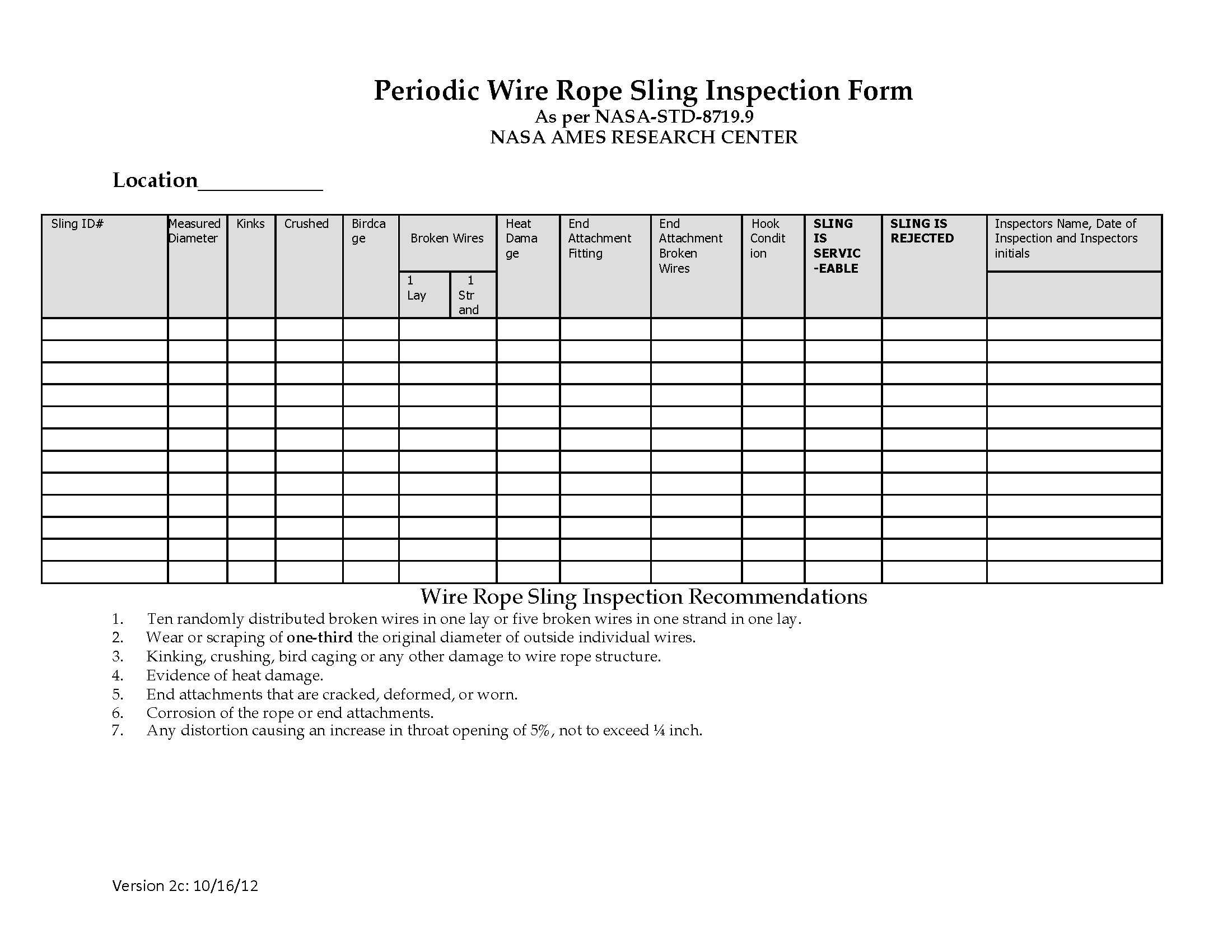

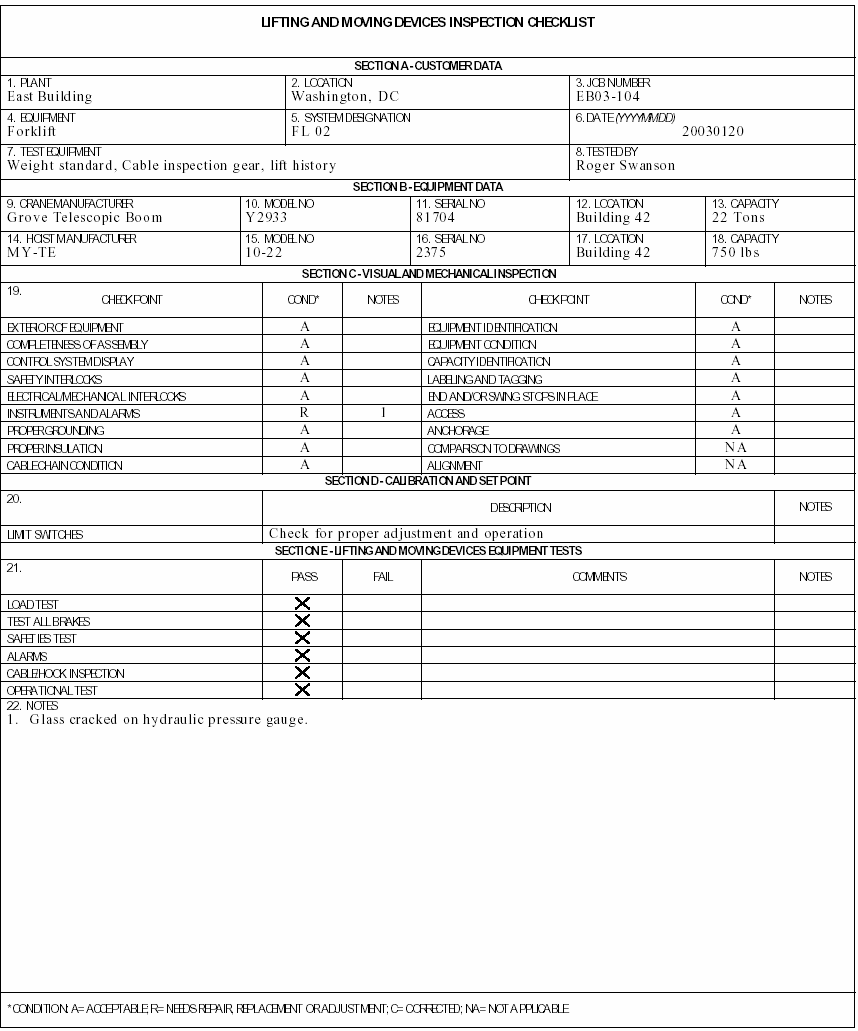

Ends of rope for excessive wear. Particularly check ends of rope action. Proper documentation of origin use and inspection of equipment is necessary to insure the integrity of rope access systems. Choose acuren s integrated rope access model to ensure the most efficient cost effective inspection for equipment in nearly any industry.

Forms from cmc s rope rescue manual and confined space entry rescue manual in pdf format available as downloads for rescue professional s convenience. Equipment also check. Rope access technicians need carefully selected equipment to carry out tasks safely and eliminate the risk of a fall. A working line your main rope and a back up line your safety rope.

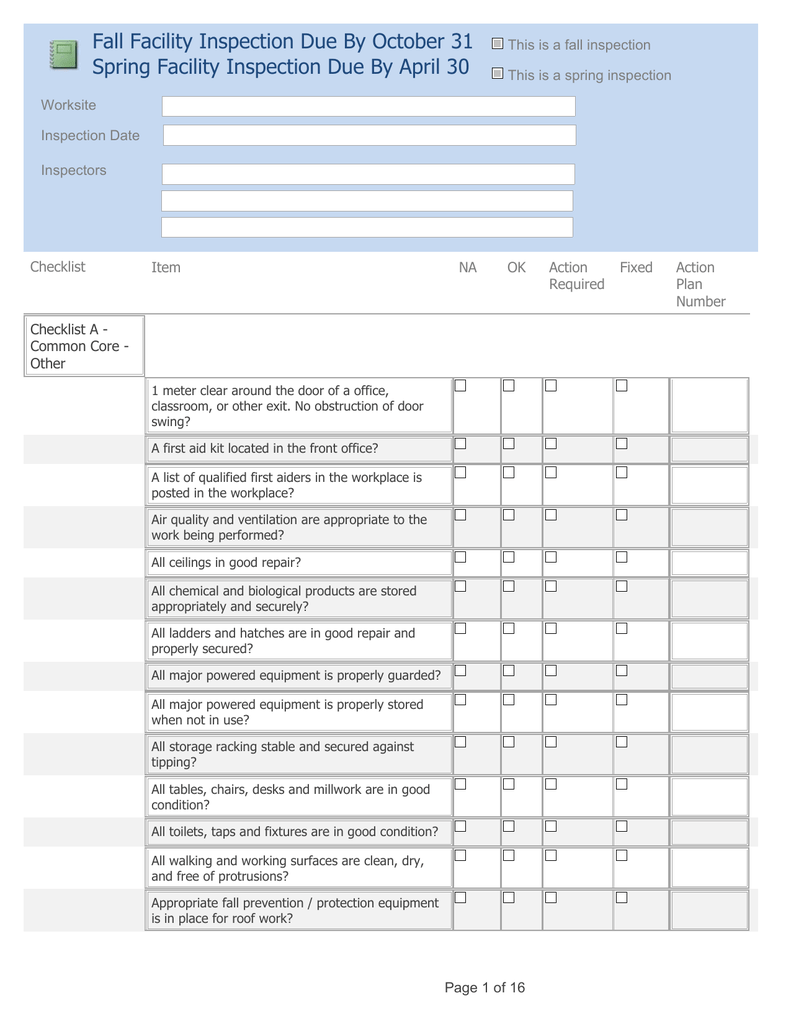

Rope access checklists if you work offshore or on major onshore construction sites you ll be familiar with pre job checklists. On cable laid ropes open up the lay and inspect as above. Inspection certification and management procedures for equipment. Equipment for use in industrial rope access work.

Read our full range of services by downloading the complete rope access integrated services brochure. Available forms include rope log hardware inspection t method air supply log entry permit incidental command system ics permits tactical log trench rescue inspection incident command chart site safety worksheet technician resource. Rope access inspection services.