Rope Brake Dynamometer Working Principle

A dynamometer or dyno for short is a device for simultaneously measuring the torque and rotational speed of an engine motor or other rotating prime mover so that its instantaneous power may be calculated and usually displayed by the dynamometer itself as kw or bhp.

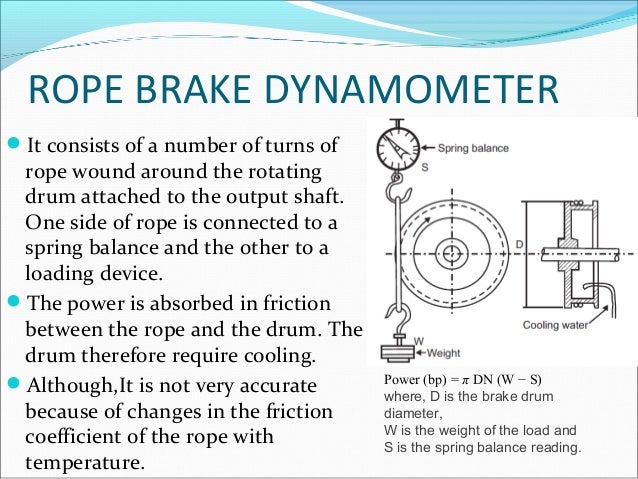

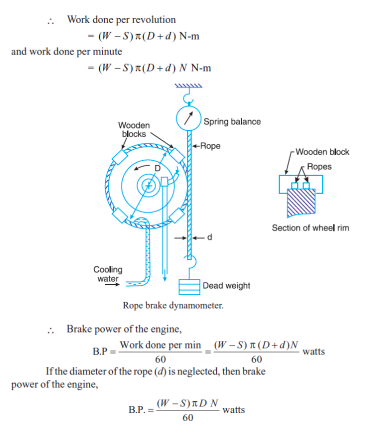

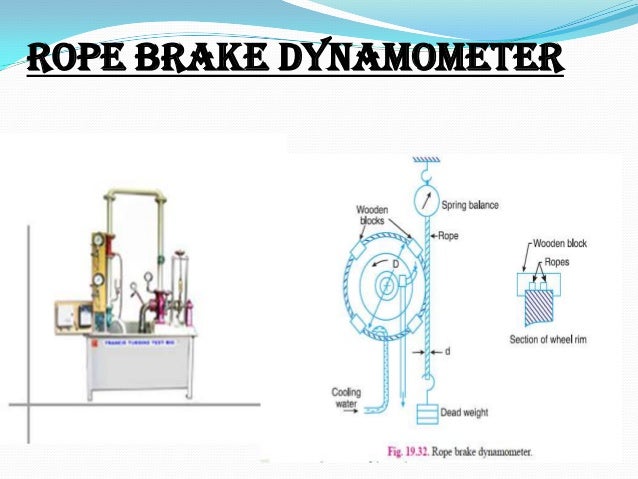

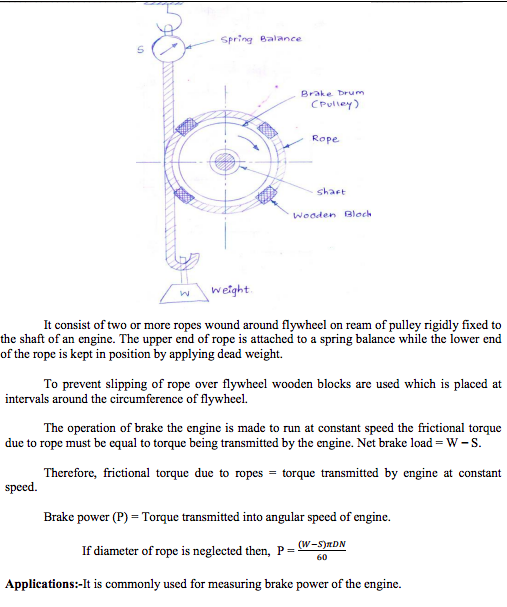

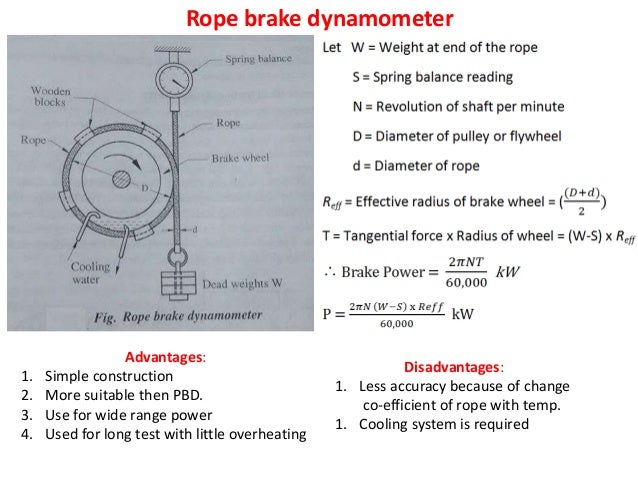

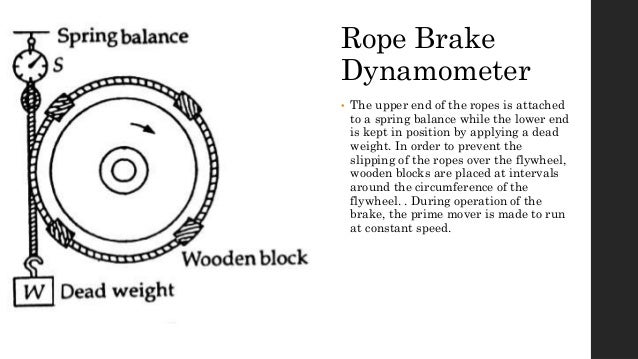

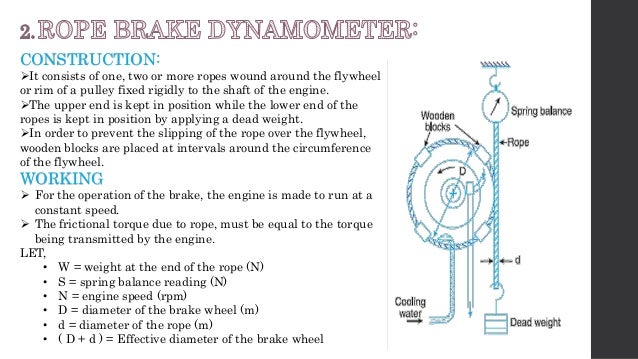

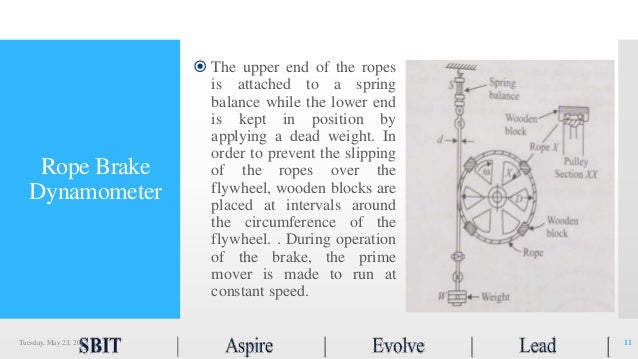

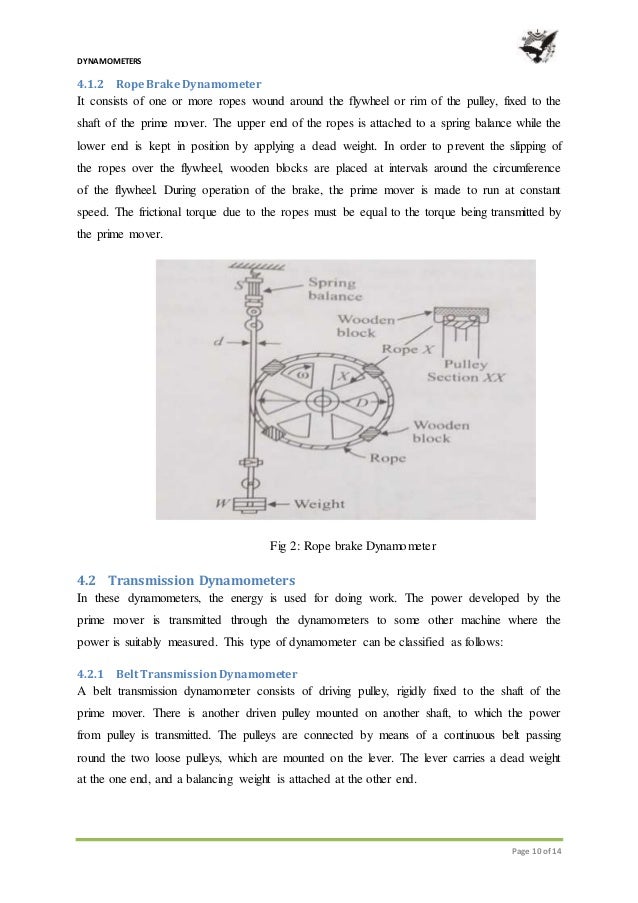

Rope brake dynamometer working principle. This type of dynamometer is cheap and can be made quickly. The power is absorbed when friction is produced between rope and drum. Rope brake dynamometer department of mechanical engineering svpcet 2013 2014 7 chapter 3 working principle 3 1parts of a rope brake dynamometer. Rope brake dynamometer anand kumar singh.

However braking power is not accurately measured due to change in the friction coefficient of the rope with the change in temperature. This gadget likewise measures the brake power and comprises of a few turns of rope that is twisted around the pivoting drum settled on the yield shaft. To find the tare support the brake on the edge at b and weigh the tare on the scales. A water brake creates a resistance by read more.

In this brake two or more ropes rest on the rim of a pulley. Therefore s l r f for balance of dynamometer. Rope brake dynamometers are cheap and can be constructed easily but brake power can t be measured accurately because of change in the friction coefficient of the rope with change in temperature. He invented the prony brake 1821 a device for measuring.

Brake power bp π dn w s. Figure 25 8 shows a rope brake dynamometer. Work done 2 r f now external torque s l where s is the scale reading and l is the length of dynamometer arm. The brake power is given by the formula brake power bp π dn w s where d is the brake drum.

Construction and working of rope brake dynamometer video lecture from chapter brakes and dynamometers in theory of machine for mechanical engineering students. Watch previous videos of chapter. Rope brake dynamometer department of mechanical engineering svpcet 2013 2014 6 chapter 3 working principle 15. Skip navigation sign in.

Therefore drum in rope brake requires cooling. One end of the rope is associated with the stacking gadget and another conclusion to the spring balance. A prony brake see figure develops mechanical friction on the periphery of a rotating pulley by means of brake blocks that are squeezed against the wheel by tightening the bolts until the friction torque fr balances the torque wl. The working principle and notes that helps in exam for mechanical engineering students.

Thus the net force on the scales produced by the frictional moment is p tare. In gaspard de prony. Brake power is given by. The basic parts of a rope brake dynamometer are as follows.